back to collapsologie |

rat haus |

Index |

Search |

tree

The following are excerpts from:

These excerpts contain inline segments of the map—linked to

full-size map segments—and endnote references within

[square braces] in the paragraphs where the endnote numbers appear

in the original text. A majority of references link to complete

online sources. Additional hyperlink references have been added

to facilitate further study of sources cited.

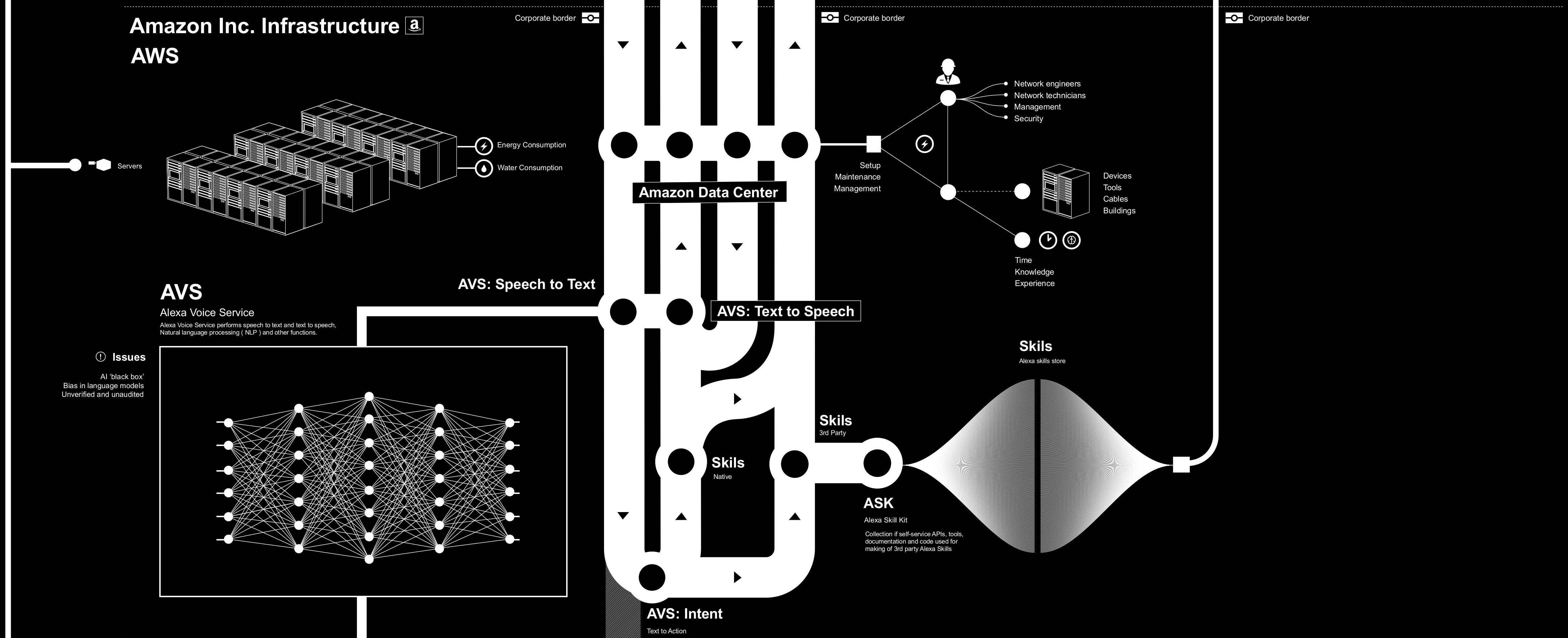

II

With each interaction, Alexa is training to hear better, to

interpret more precisely, to trigger actions that map to the

user’s commands more accurately, and to build a more

complete model of their preferences, habits and desires. What is

required to make this possible? Put simply: each small moment of

convenience – be it answering a question, turning on a

light, or playing a song – requires a vast planetary

network, fueled by the extraction of non-renewable materials,

labor, and data. The scale of resources required is many

magnitudes greater than the energy and labor it would take a

human to operate a household appliance or flick a switch. A full

accounting for these costs is almost impossible, but it is

increasingly important that we grasp the scale and scope if we

are to understand and govern the technical infrastructures that

thread through our lives.

IV

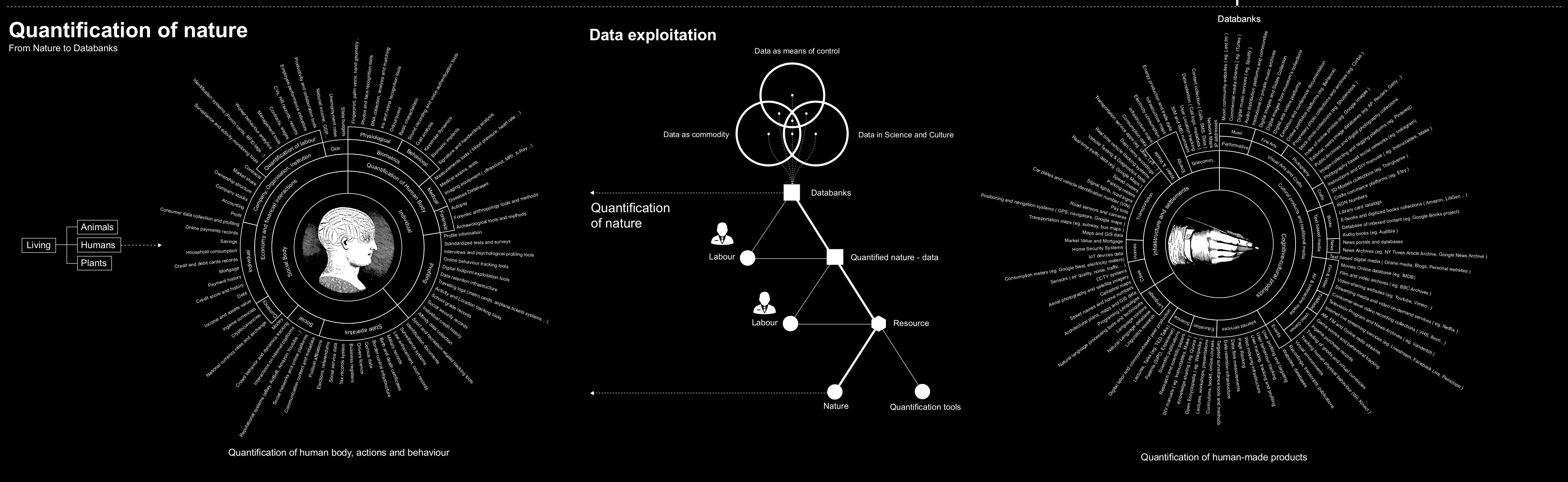

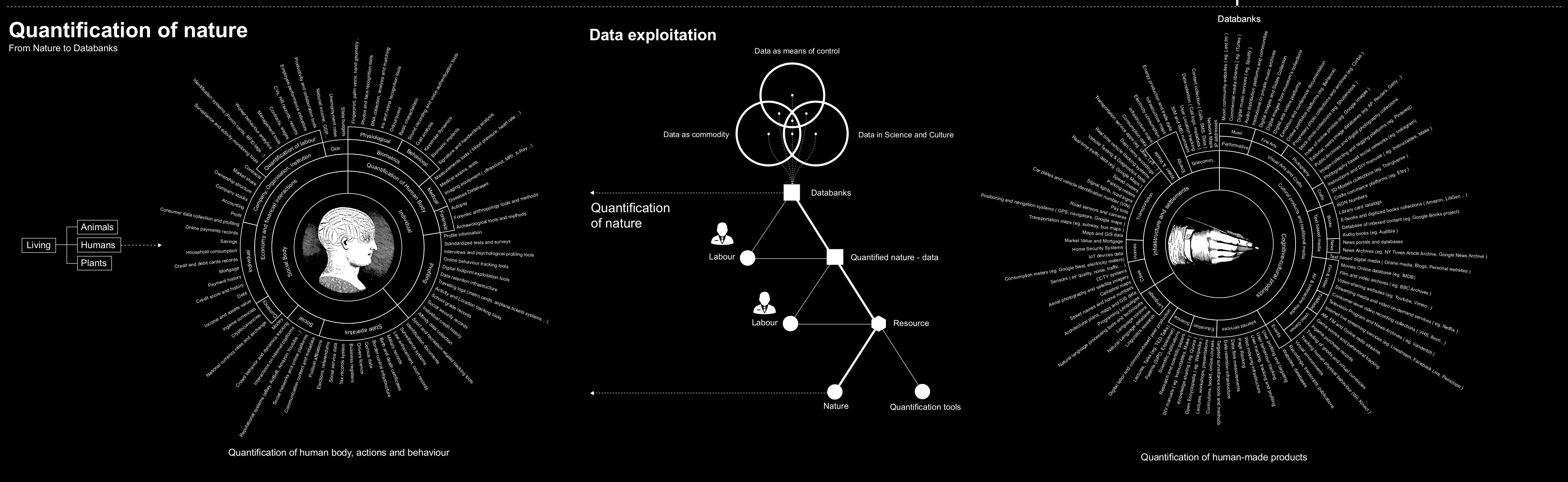

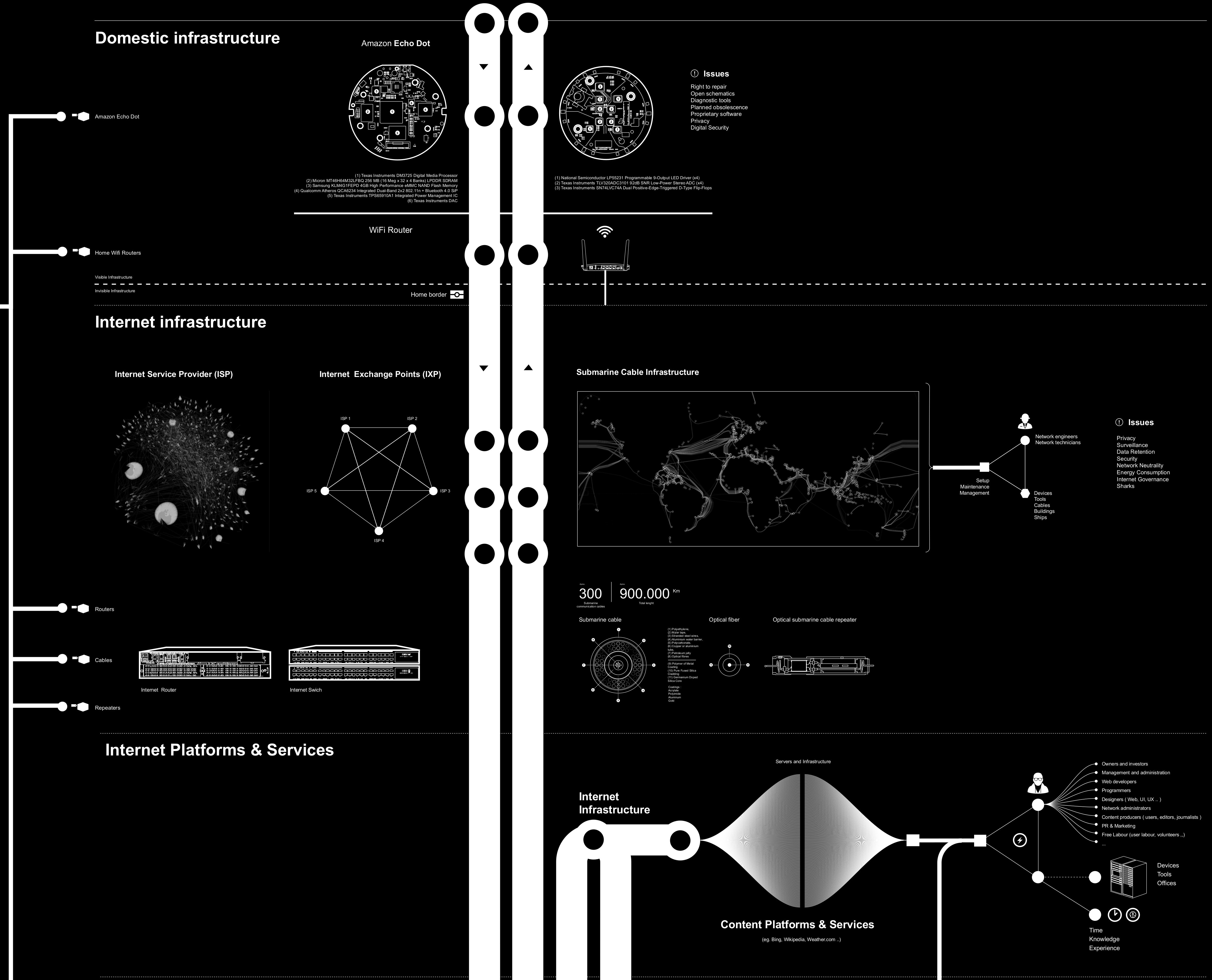

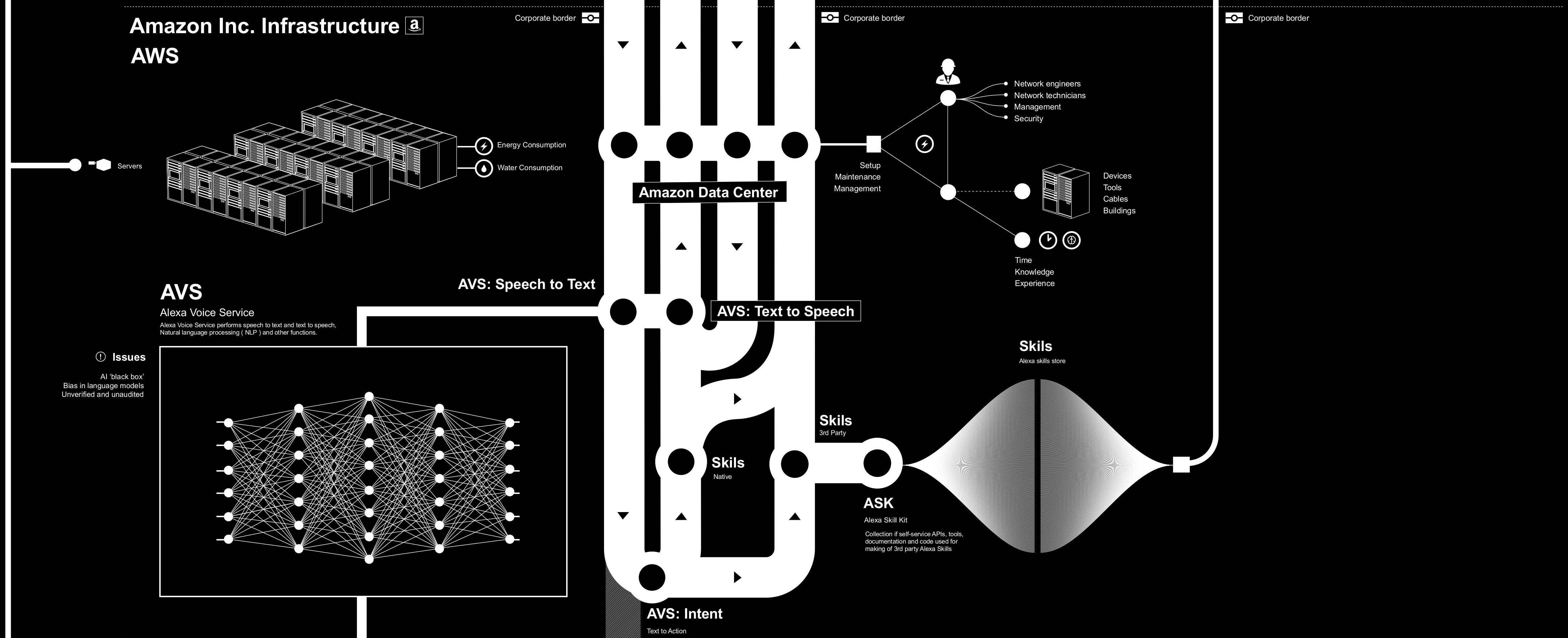

Our exploded view diagram combines and visualizes three central,

extractive processes that are required to run a large-scale

artificial intelligence system:

material resources, human labor, and data. We consider these three elements across time —

represented as a visual description of the birth, life and death

of a single Amazon Echo unit. It’s necessary to move beyond

a simple analysis of the relationship between an individual

human, their data, and any single technology company in order to

contend with with the truly planetary scale of extraction.

Vincent Mosco has shown how the ethereal metaphor of

‘the cloud’

for offsite data management and processing is in

complete contradiction with the physical realities of the

extraction of minerals from the Earth’s crust and

dispossession of human populations that sustain its existence.

[Vincent Mosco,

To the Cloud: Big Data in a Turbulent World

(Boulder: Paradigm, 2014)

isbn.nu]

Sandro Mezzadra

and Brett Nielson use the term

‘extractivism’ to name the relationship between

different forms of extractive operations in contemporary

capitalism, which we see repeated in the context of the AI

industry.

[Sandro Mezzadra

and

Brett Neilson,

“On the Multiple Frontiers of Extraction: Excavating Contemporary Capitalism,”

Cultural Studies 31, no. 2-3 (May 4, 2017): 185.]

There are deep interconnections between the literal

hollowing out of the materials of the earth and biosphere, and

the data capture and monetization of human practices of

communication and sociality in AI. Mezzadra and Nielson note that

labor is central to this extractive relationship, which has

repeated throughout history: from the way European imperialism

used slave labor, to the forced work crews on rubber plantations

in Malaya, to the Indigenous people of Bolivia being driven to

extract the silver that was used in the first global currency.

Thinking about extraction requires thinking about labor,

resources, and data together. This presents a challenge to

critical and popular understandings of artificial intelligence:

it is hard to ‘see’ any of these processes

individually, let alone collectively. Hence the need for a

visualization that can bring these connected, but globally

dispersed processes into a single map.

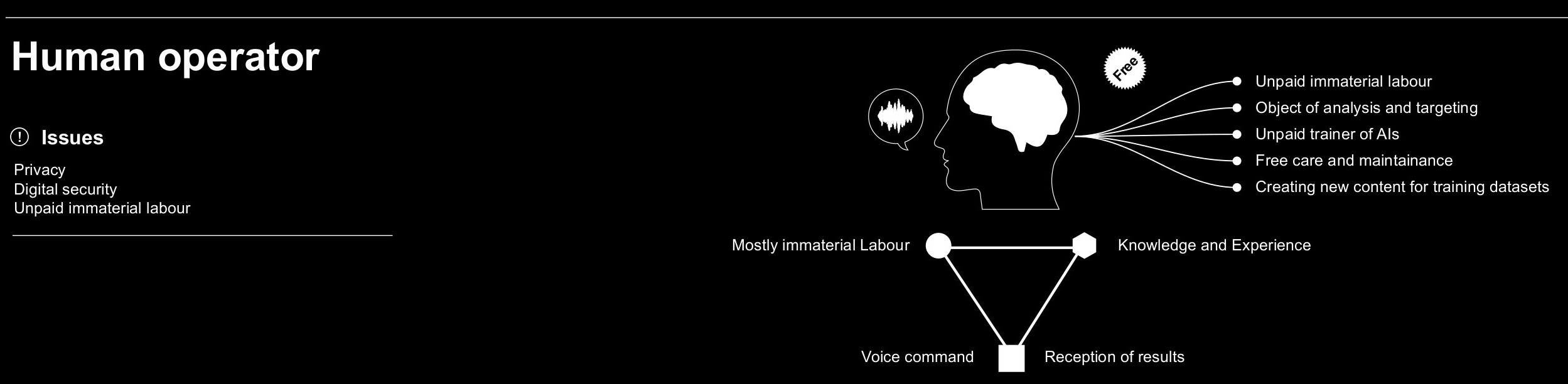

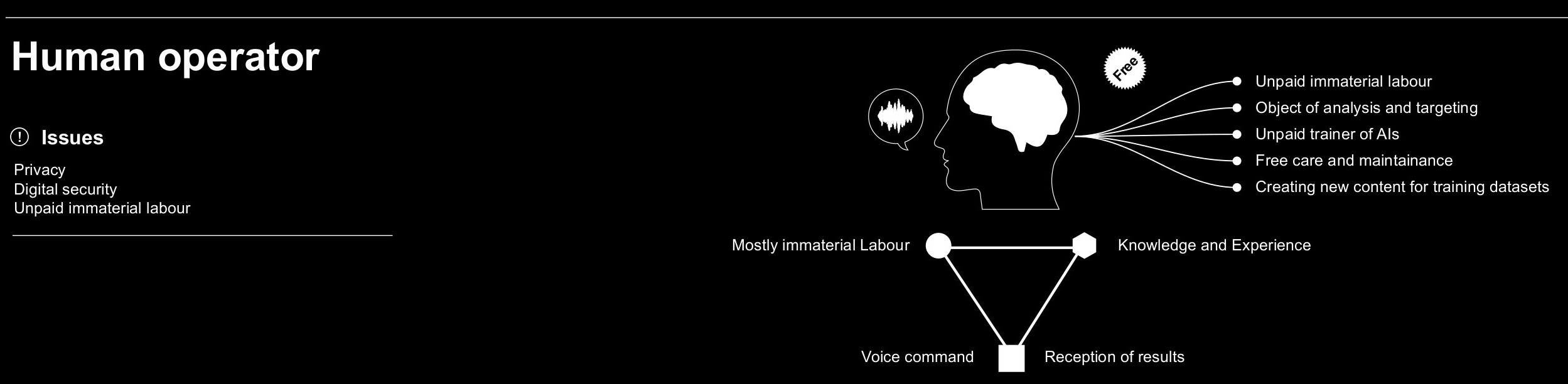

Human Agent Freely Supplies AZ With Valuable Training Data

V

If you read our map from left to right, the story begins and ends

with the Earth, and the geological processes of deep time. But

read from top to bottom, we see the story as it begins and ends

with a human. The top is the human agent, querying the Echo, and

supplying Amazon with the valuable training data of verbal

questions and responses that they can use to further refine their

voice-enabled AI systems. At the bottom of the map is another

kind of human resource: the history of human knowledge and

capacity, which is also used to train and optimize artificial

intelligence systems. This is a key difference between artificial

intelligence systems and other forms of consumer technology: they

rely on the ingestion, analysis and optimization of vast amounts

of human generated images, texts and videos.

Another Kind of Human Resource: The History of Human Knowledge

VI

When a human engages with an Echo, or another voice-enabled AI

device, they are acting as much more than just an end-product

consumer. It is difficult to place the human user of an AI system

into a single category: rather, they deserve to be considered as

a hybrid case. Just as the Greek chimera was a mythological

animal that was part lion, goat, snake and monster, the Echo user

is simultaneously a consumer, a resource, a worker, and a

product. This multiple identity recurs for human users in many

technological systems. In the specific case of the Amazon Echo,

the user has purchased a consumer device for which they receive a

set of convenient affordances. But they are also a resource, as

their voice commands are collected, analyzed and retained for the

purposes of building an ever-larger corpus of human voices and

instructions. And they provide labor, as they continually perform

the valuable service of contributing feedback mechanisms

regarding the accuracy, usefulness, and overall quality of

Alexa’s replies. They are, in essence, helping to train the

neural networks within Amazon’s infrastructural stack.

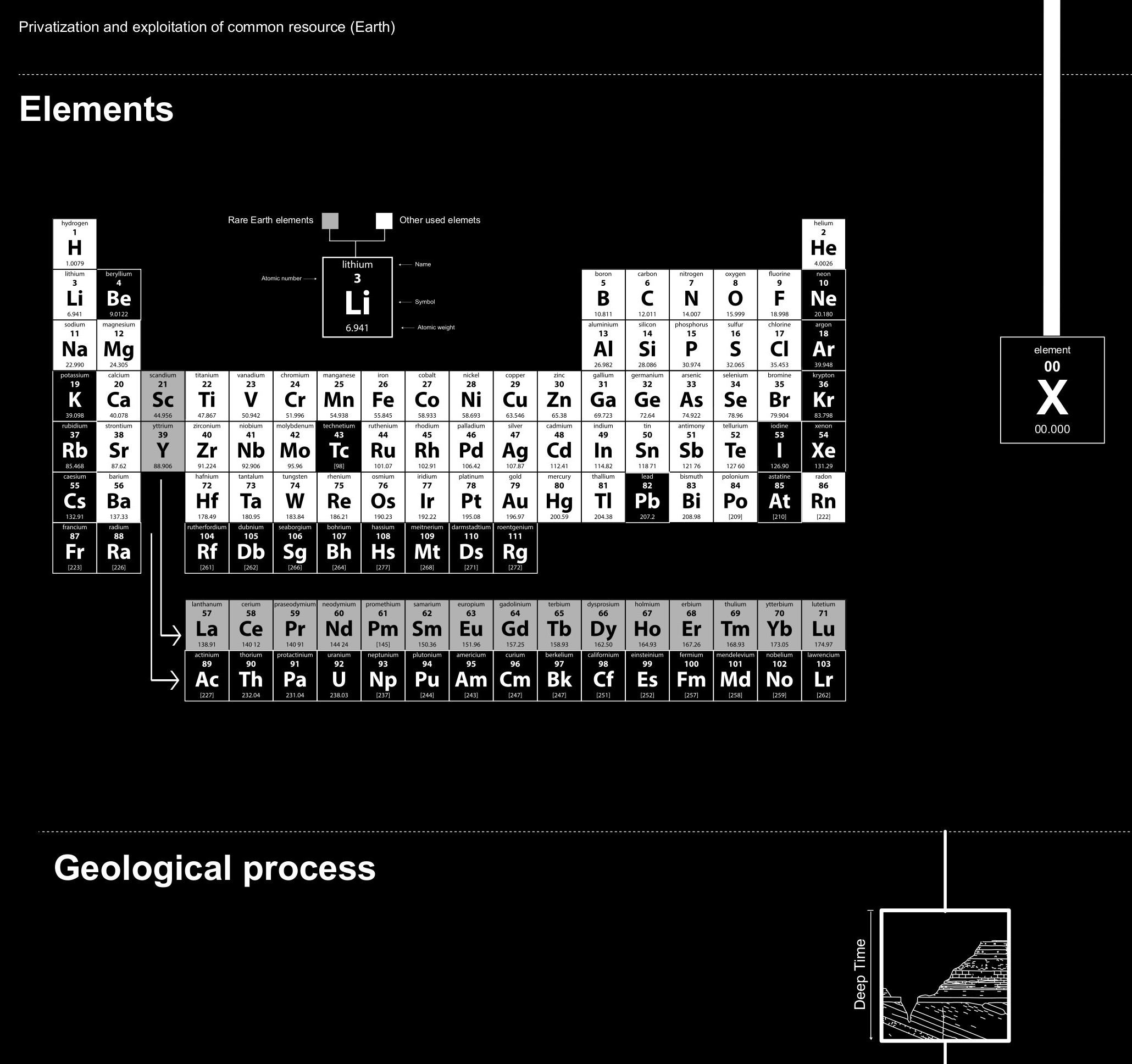

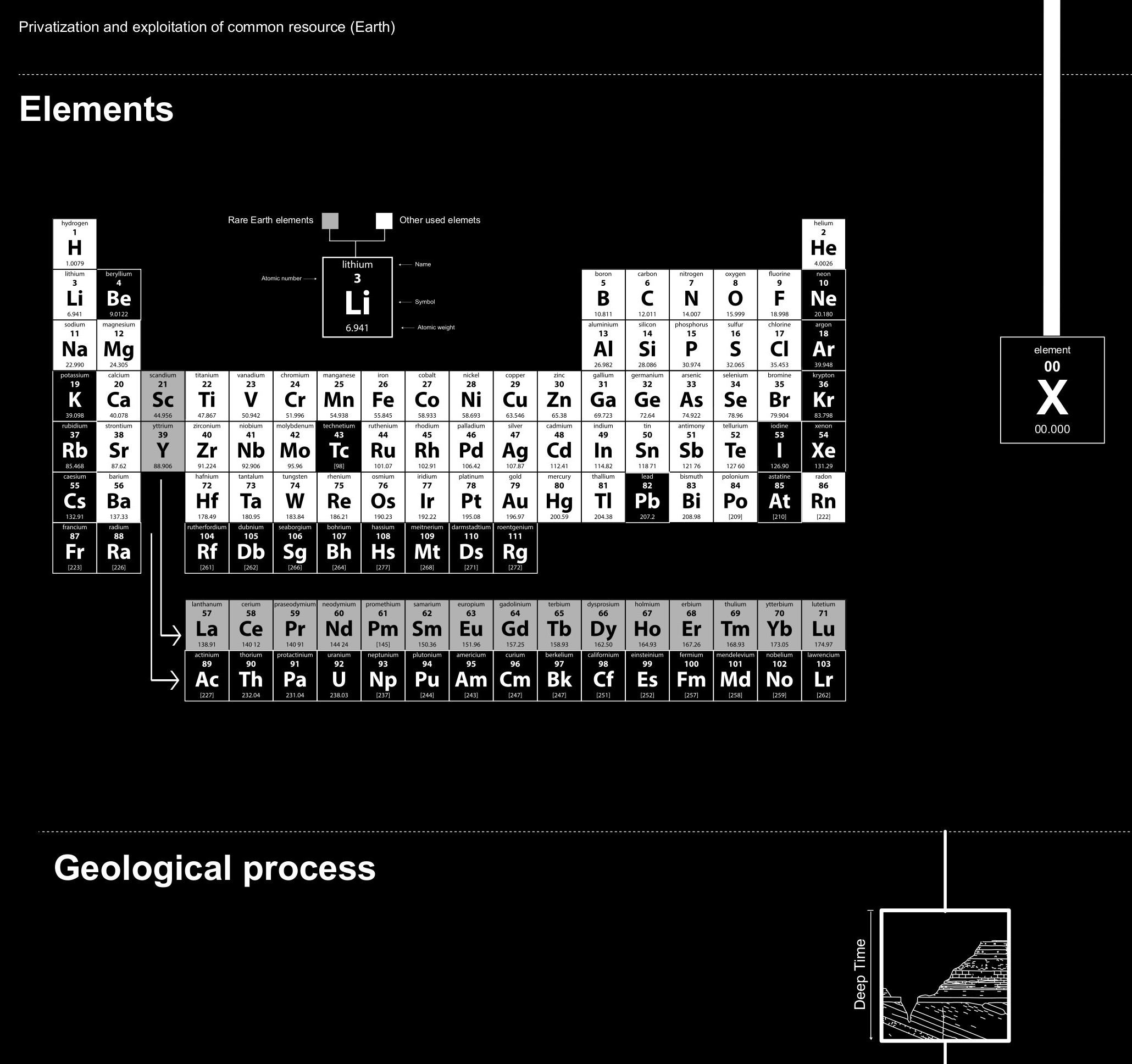

VIII

In his book

A Geology of Media,

Jussi Parikka

suggests that we

try to think of media not from Marshall McLuhan’s point of

view — in which media are extensions of human senses

— but rather as an extension of

Earth.[Jussi Parikka,

A Geology of Media

(Minneapolis:

University Of Minnesota Press, 2015),

vii-viii.] Media

technologies should be understood in context of a geological

process, from the creation and the transformation processes, to

the movement of natural elements from which media are built.

Reflecting upon media and technology as geological processes

enables us to consider the profound depletion of non-renewable

resources required to drive the technologies of the present

moment. Each object in the extended network of an AI system, from

network routers to batteries to microphones, is built using

elements that required billions of years to be produced. Looking

from the perspective of deep time, we are extracting

Earth’s history to serve a split second of technological

time, in order to build devices that are often designed to be

used for no more than a few years. For example, the Consumer

Technology Association notes that the average smartphone lifespan

is 4.7 years.[Chris Ely,

“The Life Expectancy of Electronics,”

Consumer Technology Association, 16 Sep 2014]

This obsolescence cycle fuels the purchase of

more devices, drives up profits, and increases incentives for the

use of unsustainable extraction practices. From a slow process of

elemental development, these elements and materials go through an

extraordinarily rapid period of excavation, smelting, mixing, and

logistical transport — crossing thousands of kilometers in

their transformation. Geological processes mark both the

beginning and the end of this period, from the mining of ore, to

the deposition of material in an electronic waste dump. For that

reason, our map starts and ends with the Earth’s crust.

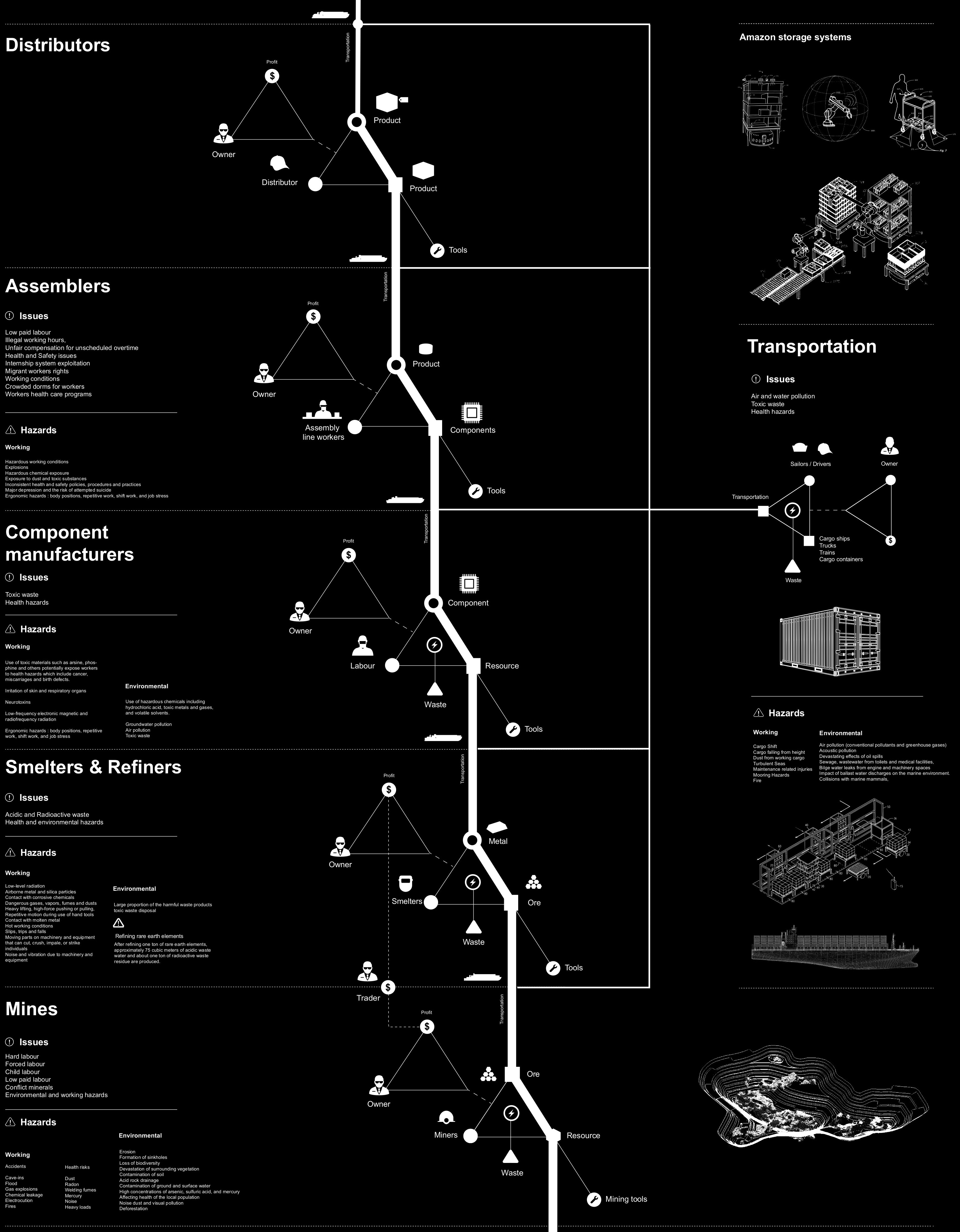

However, all the transformations and movements we depict are only

the barest anatomical outline: beneath these connections lie many

more layers of fractal supply chains, and exploitation of human

and natural resources, concentrations of corporate and

geopolitical power, and continual energy consumption.

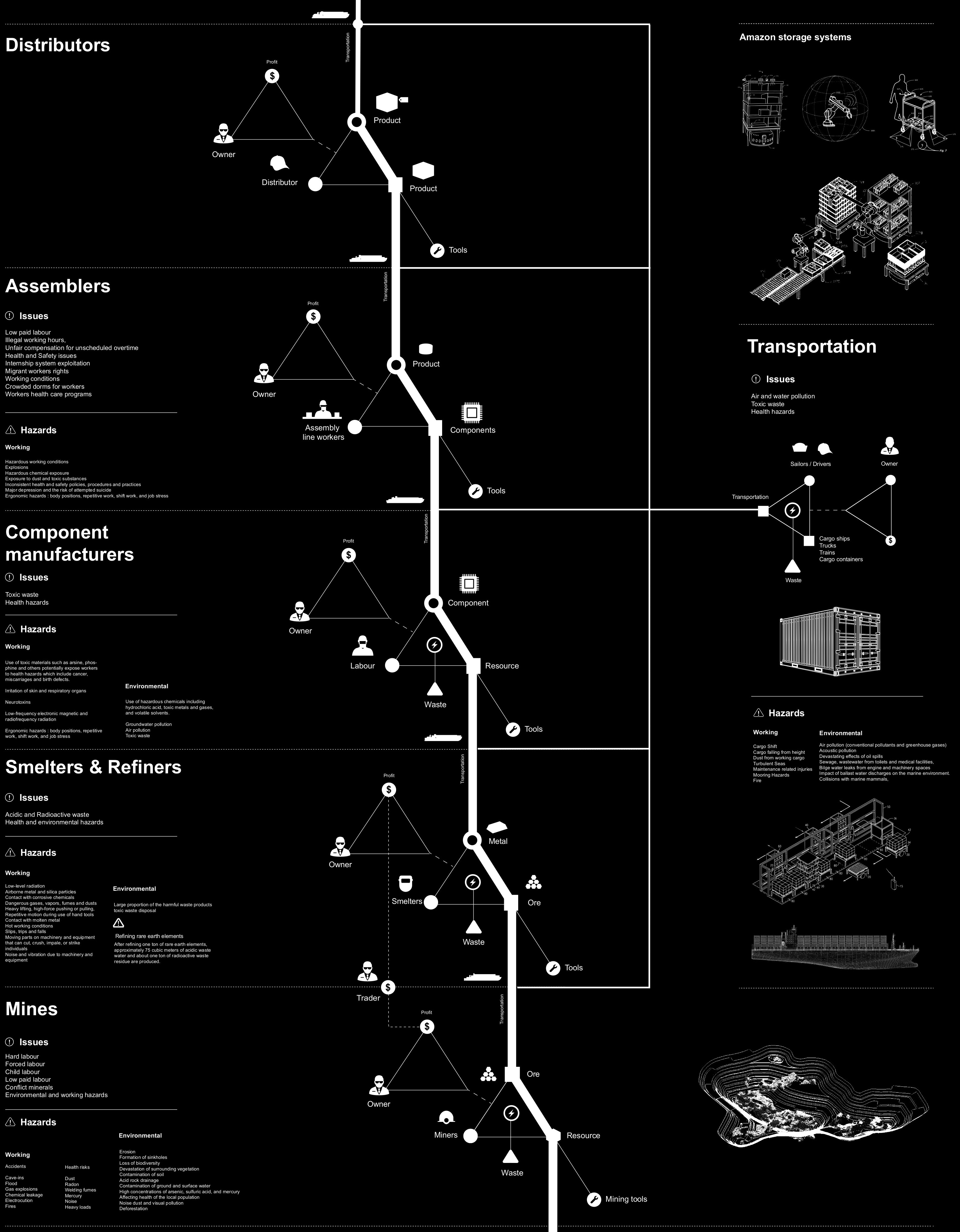

Fractal Supply Chain Layers:

Mines → Smelters & Refiners →

Component Manufacturers → Assemblers → Distributors

IX

Drawing out the connections between resources, labor and data

extraction brings us inevitably back to traditional frameworks

of exploitation. But how is value being generated through

these systems? A useful conceptual tool can be found in the

work of Christian Fuchs

and other authors examining and defining digital labor.

The notion of digital labor, which was initially linked with

different forms of non-material labor, precedes the life of

devices and complex systems such as artificial intelligence.

Digital labor — the work of building and maintaining the

stack of digital systems — is far from ephemeral or

virtual, but is deeply embodied in different activities.

[Christian Fuchs,

Digital Labor and Karl Marx

(London: Routledge, 2014)

worldcat]

The scope is overwhelming: from indentured labor in mines for

extracting the minerals that form the physical basis of

information technologies; to the work of strictly controlled and

sometimes dangerous hardware manufacturing and assembly processes

in Chinese factories; to exploited outsourced cognitive workers

in developing countries labelling AI training data sets; to the

informal physical workers cleaning up toxic waste dumps. These

processes create new accumulations of wealth and power, which are

concentrated in a very thin social layer.

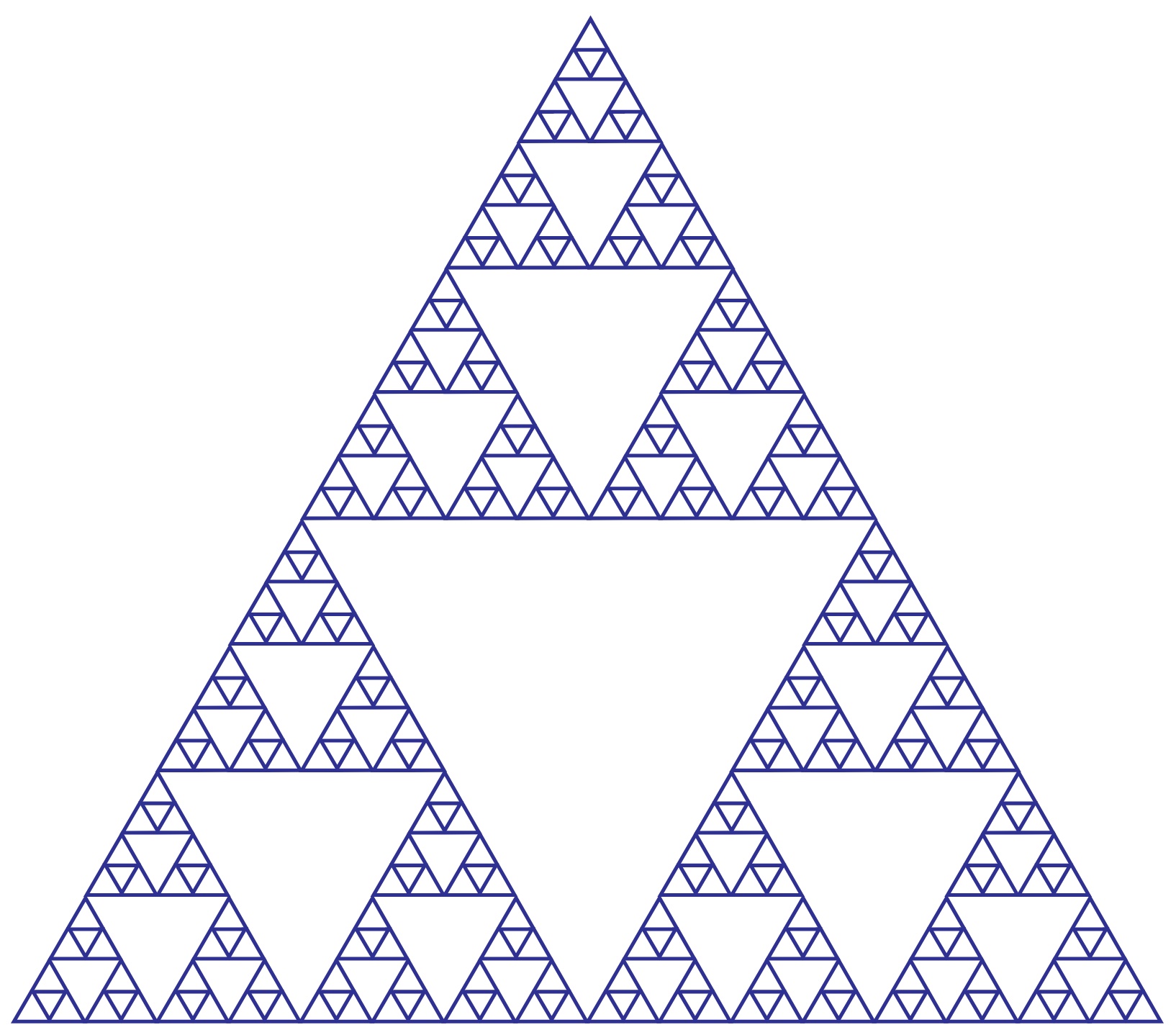

Marx’s Dialect of Subject and Object in Economy

Fractal Chains of Production and Exploitation

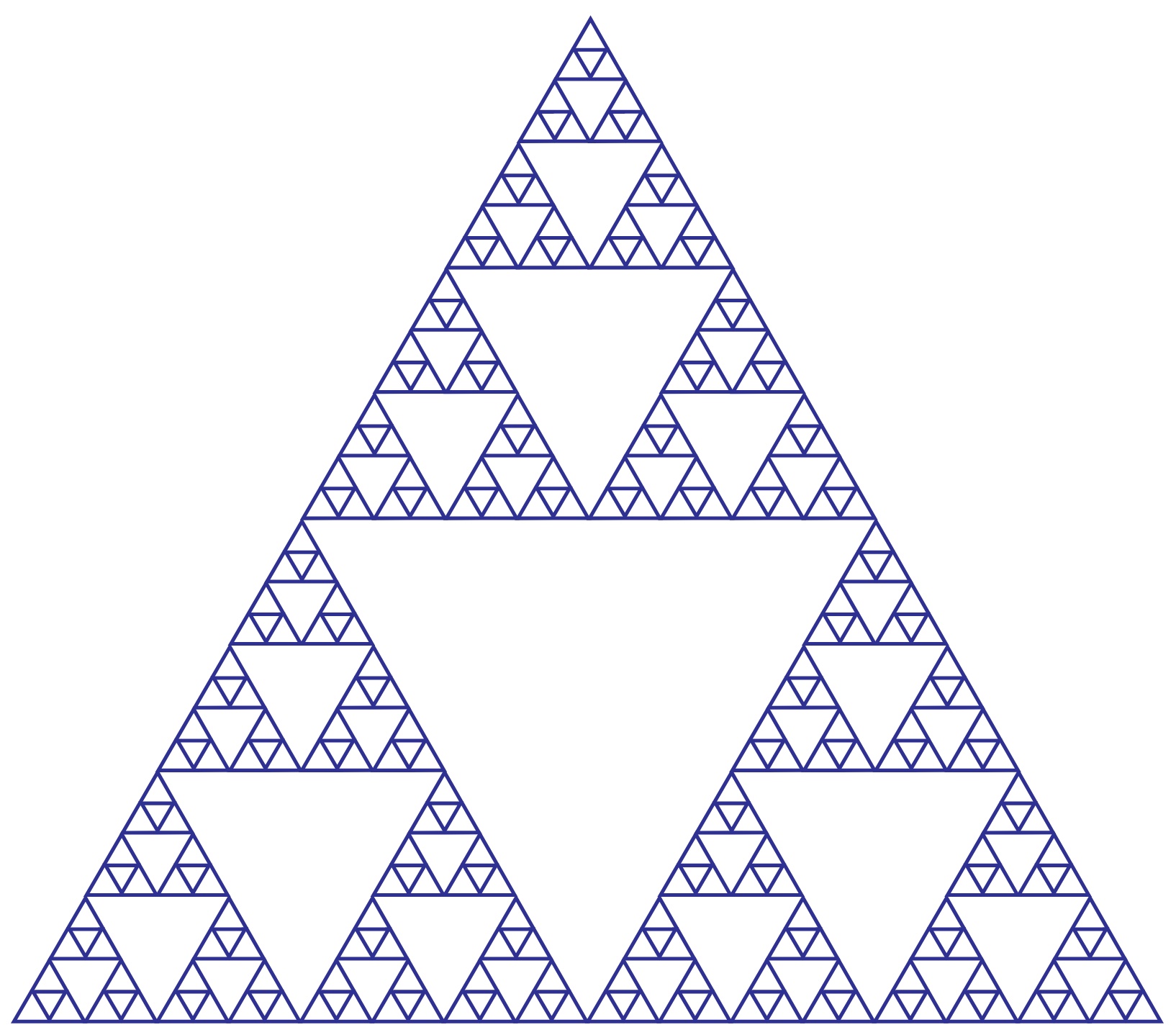

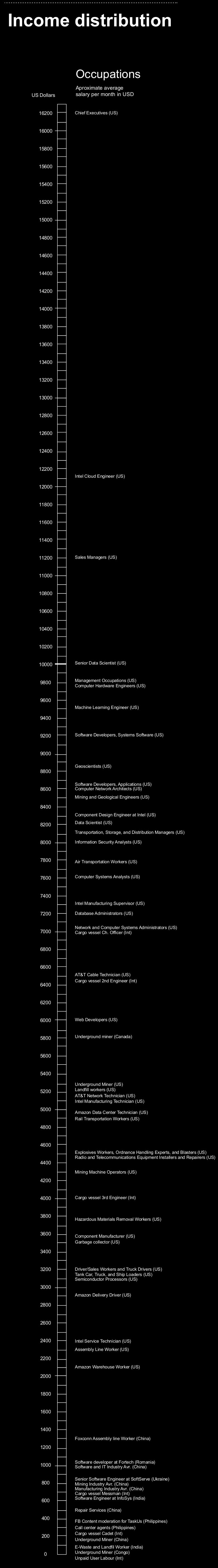

X

This triangle of value extraction and production represents one

of the basic elements of our map, from birth in a geological

process, through life as a consumer AI product, and ultimately to

death in an electronics dump. Like in Fuchs’ work, our

triangles are not isolated, but linked to one another in the

production process. They form a cyclic flow in which the product

of work is transformed into a resource, which is transformed into

a product, which is transformed into a resource and so on. Each

triangle represents one phase in the production process. Although

this appears on the map as a linear path of transformation, a

different visual metaphor better represents the complexity of

current extractivism: the fractal structure known as the

Sierpinski triangle.

A linear display does not enable us to show that each next step

of production and exploitation contains previous phases. If we

look at the production and exploitation system through a fractal

visual structure, the smallest triangle would represent natural

resources and means of labor, i.e. the miner as labor and ore as

product. The next larger triangle encompasses the processing of

metals, and the next would represent the process of manufacturing

components and so on. The ultimate triangle in our map, the

production of the Amazon Echo unit itself, includes all of these

levels of exploitation — from the bottom to the very top of

Amazon Inc, a role inhabited by Jeff Bezos as CEO of Amazon. Like

a pharaoh of ancient Egypt, he stands at the top of the largest

pyramid of AI value extraction.

Sierpinski Triangle or Sierpinski Fractal

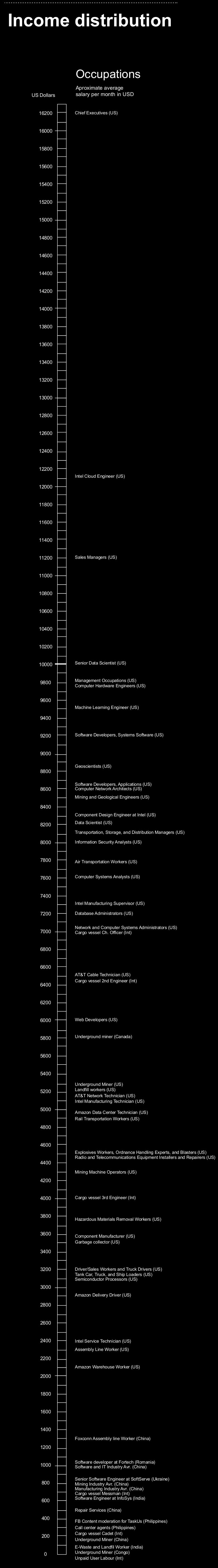

XI

To return to the basic element of this visualization—a

variation of Marx’s triangle of production—each triangle

creates a surplus of value for creating profits. If we look at

the scale of average income for each activity in the production

process of one device, which is shown on the left side of our

map, we see the dramatic difference in income earned. According

to research by Amnesty International, during the excavation of

cobalt which is also used for lithium batteries of 16

multinational brands, workers are paid the equivalent of one US

dollar per day for working in conditions hazardous to life and

health, and were often subjected to violence, extortion and

intimidation.

[“This Is What We Die For: Human Rights Abuses in the Democratic Republic of the Congo Power the Global Trade in Cobalt”

(London: Amnesty International, 2016). For an anthropological

description of these mining processes, see: Jeffrey W. Mantz,

“Improvisational Economies: Coltan Production in the Eastern Congo,”

Social Anthropology 16, no. 1 (February 1, 2008): 34-50.]

Amnesty has documented children as young as 7

working in the mines. In contrast, Amazon CEO Jeff Bezos, at the

top of our fractal pyramid, made an average of $275 million a day

during the first five months of 2018, according to the Bloomberg

Billionaires Index.[Julia Glum,

“The Median Amazon Employee’s Salary Is $28,000. Jeff Bezos Makes More Than That in 10 Seconds,”

Time, May 2, 2018.]

A child working in a mine in the Congo

would need more than 700,000 years of non-stop work to earn the

same amount as a single day of Bezos’ income.

To return to the basic element of this visualization—a

variation of Marx’s triangle of production—each triangle

creates a surplus of value for creating profits. If we look at

the scale of average income for each activity in the production

process of one device, which is shown on the left side of our

map, we see the dramatic difference in income earned. According

to research by Amnesty International, during the excavation of

cobalt which is also used for lithium batteries of 16

multinational brands, workers are paid the equivalent of one US

dollar per day for working in conditions hazardous to life and

health, and were often subjected to violence, extortion and

intimidation.

[“This Is What We Die For: Human Rights Abuses in the Democratic Republic of the Congo Power the Global Trade in Cobalt”

(London: Amnesty International, 2016). For an anthropological

description of these mining processes, see: Jeffrey W. Mantz,

“Improvisational Economies: Coltan Production in the Eastern Congo,”

Social Anthropology 16, no. 1 (February 1, 2008): 34-50.]

Amnesty has documented children as young as 7

working in the mines. In contrast, Amazon CEO Jeff Bezos, at the

top of our fractal pyramid, made an average of $275 million a day

during the first five months of 2018, according to the Bloomberg

Billionaires Index.[Julia Glum,

“The Median Amazon Employee’s Salary Is $28,000. Jeff Bezos Makes More Than That in 10 Seconds,”

Time, May 2, 2018.]

A child working in a mine in the Congo

would need more than 700,000 years of non-stop work to earn the

same amount as a single day of Bezos’ income.

Many of the triangles shown on this map hide different stories of

labor exploitation and inhumane working conditions. The

ecological price of transformation of elements and income

disparities is just one of the possible ways of representing a

deep systemic inequality. We have both researched different forms

of ‘black boxes’ understood as algorithmic

processes,[Frank Pasquale,

The Black Box Society: The Secret Algorithms That Control Money and Information,

(Cambridge, MA: Harvard Univ Press, 2016).]

but this map points to another form of opacity: the very

processes of creating, training and operating a device like an

Amazon Echo is itself a kind of black box, very hard to examine

and track in toto given the multiple layers of contractors,

distributors, and downstream logistical partners around the

world. As Mark Graham writes, “contemporary capitalism

conceals the histories and geographies of most commodities from

consumers. Consumers are usually only able to see commodities in

the here and now of time and space, and rarely have any

opportunities to gaze backwards through the chains of production

in order to gain knowledge about the sites of production,

transformation, and distribution.”[Mark Graham and

Håvard Haarstad,

“Transparency and Development: Ethical Consumption through Web 2.0 and the Internet of Things,”

Information Technologies & International Development

7, no.1 10 March 2011.]

One illustration of the difficulty of investigating and tracking

the contemporary production chain process is that it took Intel

more than four years to understand its supply line well enough to

ensure that no tantalum from the Congo was in its microprocessor

products. As a semiconductor chip manufacturer, Intel supplies

Apple with processors. In order to do so, Intel has its own

multi-tiered supply chain of more than 19,000 suppliers in over

100 countries providing direct materials for their production

processes, tools and machines for their factories, and logistics

and packaging services.

[“Intel’s Efforts to Achieve a ‘Conflict Free’ Supply Chain”

(Santa Clara, CA: Intel Corporation, May 2016) {For comparison, see

altered May 2019 edition:

“Intel’s Efforts to Achieve a Responsibly Sourced MineralSupply Chain”}]

That it took over four years for a

leading technology company just to understand its own supply

chain, reveals just how hard this process can be to grasp from

the inside, let alone for external researchers, journalists and

academics. Dutch-based technology company Philips has also

claimed that it was working to make its supply chain

‘conflict-free’. Philips, for example, has tens of

thousands of different suppliers, each of which provides

different components for their manufacturing

processes.[“We Are Working to Make Our Supply Chain ‘Conflict-Free’,”

Philips, 2018.] Those

suppliers are themselves linked downstream to tens of thousands

of component manufacturers that acquire materials from hundreds

of refineries that buy ingredients from different smelters, which

are supplied by unknown numbers of traders that deal directly

with both legal and illegal mining operations. In The Elements of

Power, David S. Abraham describes the invisible networks of rare

metals traders in global electronics supply chains: “The

network to get rare metals from the mine to your laptop travels

through a murky network of traders, processors, and component

manufacturers. Traders are the middlemen who do more than buy and

sell rare metals: they help to regulate information and are the

hidden link that helps in navigating the network between metals

plants and the components in our

laptops.”[David S. Abraham,

The Elements of Power: Gadgets, Guns, and the Struggle for a Sustainable Future in the Rare Metal Age, Reprint edition (Yale University Press, 2017), 89. (isbn.nu)]

According to

the computer manufacturing company Dell, complexities of the

metal supply chain pose almost insurmountable

challenges.[“Responsible Minerals Sourcing,” Dell, 2018.

{Notice how terminology has been “cleaned”: the 2016 version of

this page is titled, “Addressing Conflict Minerals”.}]

The mining of these minerals takes place long before a final product

is assembled, making it exceedingly difficult to trace the

minerals’ origin. In addition, many of the minerals are

smelted together with recycled metals, by which point it becomes

all but impossible to trace the minerals to their source. So we

see that the attempt to capture the full supply chain is a truly

gargantuan task: revealing all the complexity of the 21st century

global production of technology products.

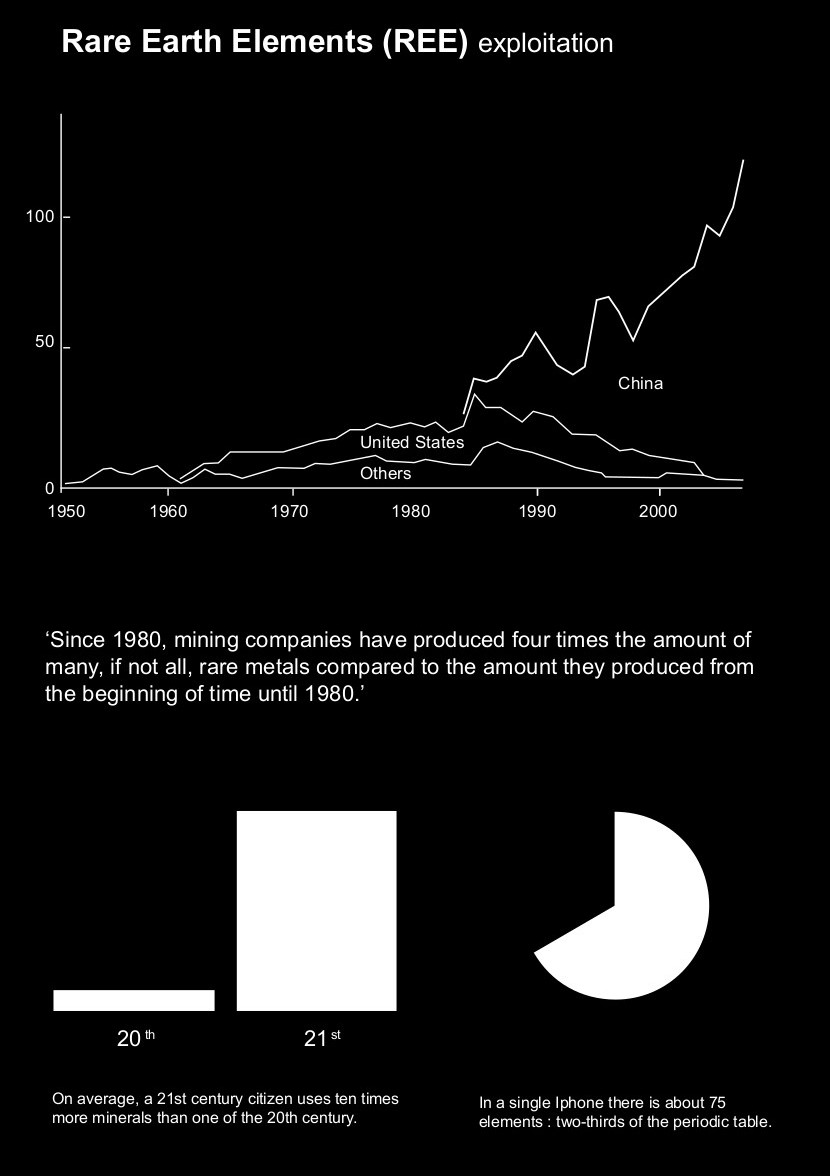

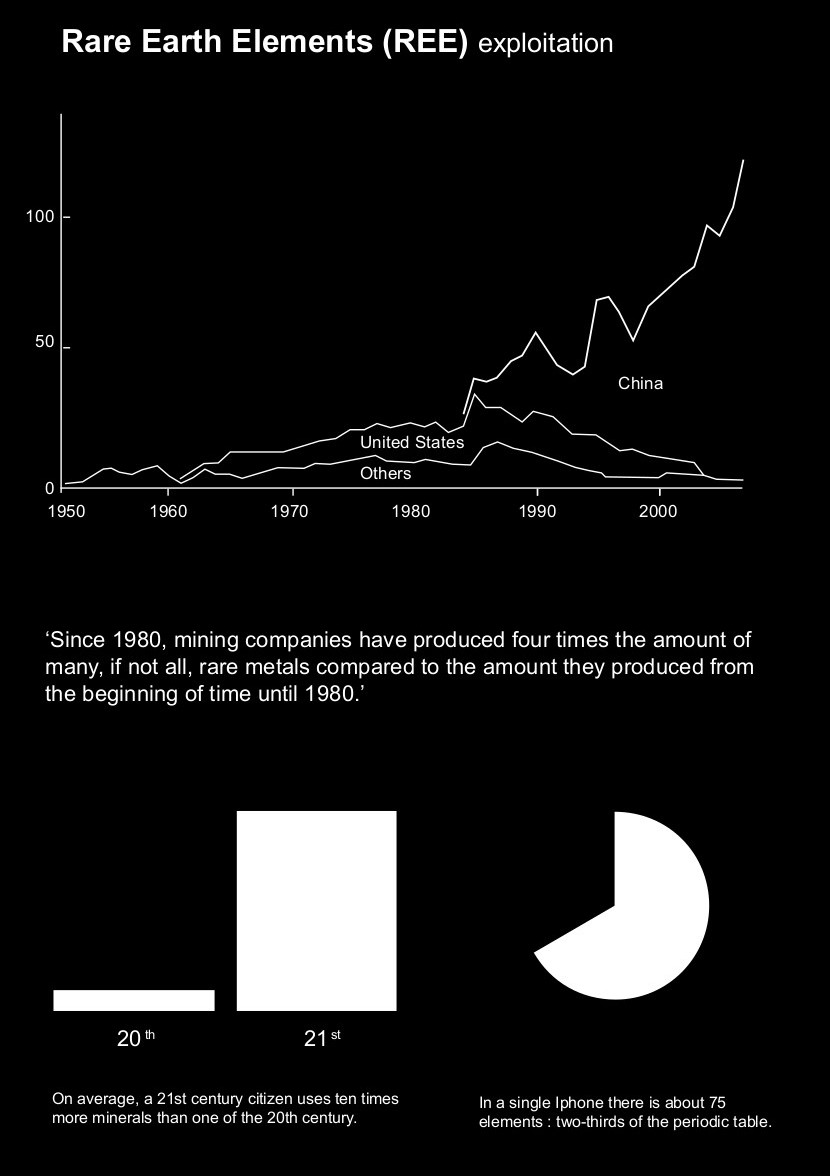

Rare Earth Elements (REE) exploitation

XII

Supply chains are often layered on top of one another, in a

sprawling network. Apple’s supplier program reveals there

are tens of thousands of individual components embedded in their

devices, which are in turn supplied by hundreds of different

companies. In order for each of those components to arrive on the

final assembly line where it will be assembled by workers in

Foxconn facilities, different components need to be physically

transferred from more than 750 supplier sites across 30 different

countries.[“Apple Supplier Responsibility 2018 Progress Report” (Cupertino CA: Apple, 2018).]

This becomes a complex structure of supply chains

within supply chains, a zooming fractal of tens of thousands of

suppliers, millions of kilometers of shipped materials and

hundreds of thousands of workers included within the process even

before the product is assembled on the line.

Cargo Ships carry 90% of internationally traded goods

Visualizing this process as one global, pancontinental network

through which materials, components and products flow, we see an

analogy to the global information network. Where there is a

single internet packet travelling to an Amazon Echo, here we can

imagine a single cargo

container.[Alexander Klose,

The Container Principle: How a Box Changes the Way We Think, trans. Charles Marcum II (Cambridge, MA: The MIT Press, 2015).

worldcat]

The dizzying spectacle of

global logistics and production will not be possible without the

invention of this simple, standardized metal object. Standardized

cargo containers allowed the explosion of modern shipping

industry, which made it possible to model the planet as a

massive, single factory. In 2017, the capacity of container ships

in seaborne trade reached nearly 250,000,000 dead-weight tons of

cargo, dominated by giant shipping companies like Maersk of

Denmark, the Mediterranean Shipping Company of Switzerland, and

France’s CMA CGM Group, each owning hundreds of container

vessels.[“Review of Maritime Transport 2017” (New York and Geneva: United Nations, 2017).]

For these commercial ventures, cargo shipping is a

relatively cheap way to traverse the vascular system of the

global factory, yet it disguises much larger external costs.

Shipping Containers

Shipping Containers, 2007 60x120"

Depicts 38,000 shipping containers,

the number of containers processed through American ports every twelve hours.

go to source and Click the image to zoom

Chris Jordan

In recent years, shipping boats produce 3.1% of global yearly CO2

emissions, more than the entire country of

Germany.[Zoë Schlanger,

“If Shipping Were a Country, It Would Be the Sixth-Biggest Greenhouse Gas Emitter,” Quartz, April 17, 2018.]

In order to minimize their internal costs, most of the container shipping

companies use very low grade fuel in enormous quantities, which

leads to increased amounts of sulphur in the air, among other

toxic substances. It has been estimated that one container ship

can emit as much pollution as 50 million cars, and 60,000 deaths

worldwide are attributed indirectly to cargo ship industry

pollution related issues annually.[John Vidal, “Health Risks of Shipping Pollution Have Been ‘Underestimated’,” The Guardian,

9 Apr 2009, sec. Environment.]

Even industry-friendly

sources like the World Shipping Council admit that thousands of

containers are lost each year, on the ocean floor or drifting

loose.[“Containers Lost At Sea—2017 Update” (World Shipping Council, July 10, 2017).]

Some carry toxic substances which leak into the oceans.

Typically, workers spend 9 to 10 months in the sea, often with

long working shifts and without access to external

communications. Workers from the Philippines represent more than

a third of the global shipping workforce.[Rose George, Ninety Percent of Everything: Inside Shipping, the Invisible Industry That Puts Clothes on Your Back, Gas in Your Car, and Food on Your Plate (New York: Metropolitan Books, 2013), 22.

Similar to our habit to neglect materiality of

internet infrastructure and information technology, shipping industry

is rarely represented in popular culture. Rose George calls this

condition, “sea blindness” (2013, 4).]

The most severe costs of global logistics are born by the

atmosphere, the oceanic ecosystem and all it contains,

and the lowest paid workers.

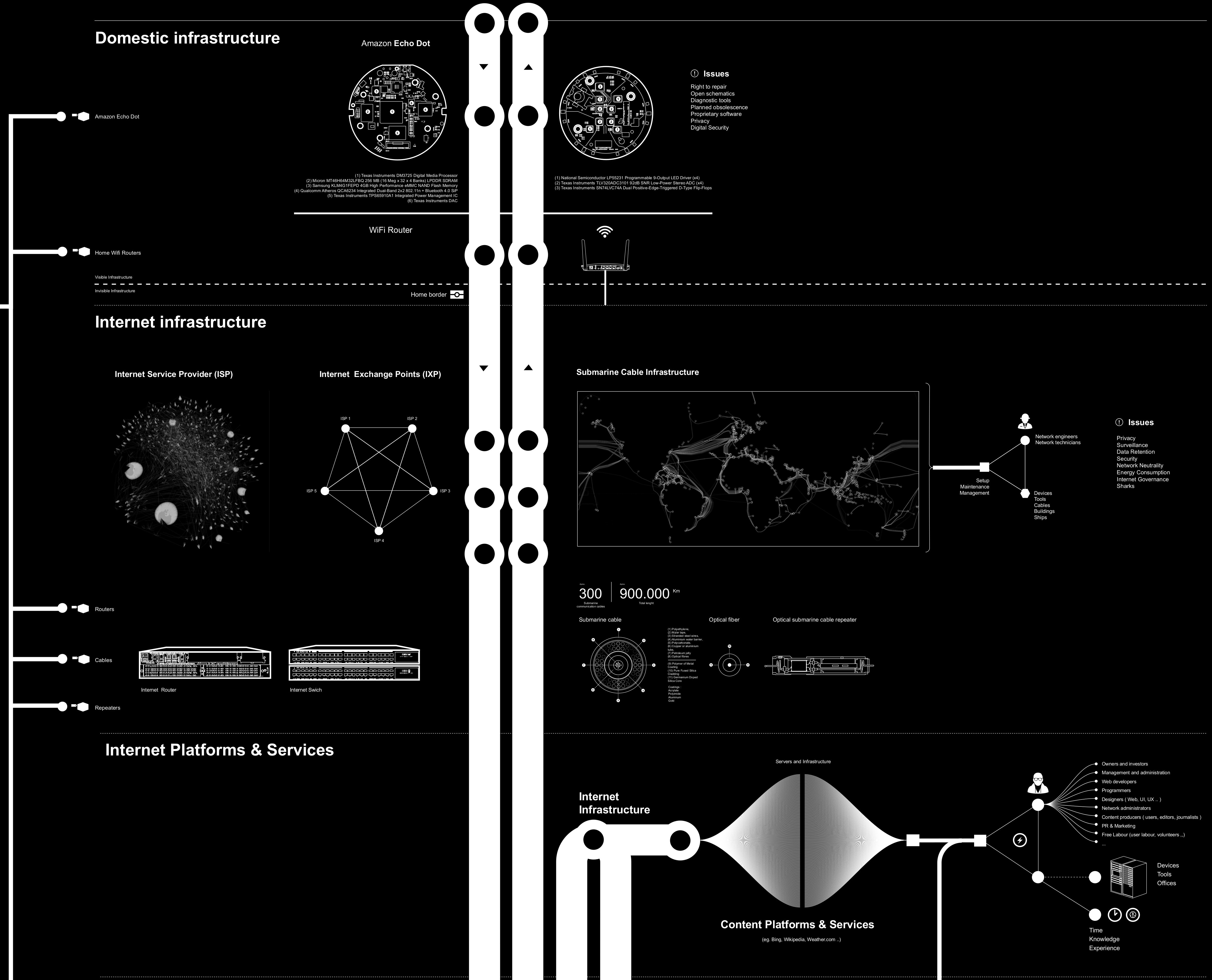

Domestic and Internet Infrastructure, Platforms & Services

XIII

The increasing complexity and miniaturization of our technology

depends on the process that strangely echoes the hopes of early

medieval alchemy. Where medieval alchemists aimed to transform

base metals into ‘noble’ ones, researchers today use

rare earth metals to enhance the performance of other minerals.

There are 17 rare earth elements, which are embedded in laptops

and smartphones, making them smaller and lighter. They play a

role in color displays, loudspeakers, camera lenses, GPS systems,

rechargeable batteries, hard drives and many other components.

They are key elements in communication systems from fiber optic

cables, signal amplification in mobile communication towers to

satellites and GPS technology. But the precise configuration and

use of these minerals is hard to ascertain. In the same way that

medieval alchemists hid their research behind cyphers and cryptic

symbolism, contemporary processes for using minerals in devices

are protected behind NDAs and trade secrets.

The unique electronic, optical and magnetic characteristics of

rare earth elements cannot be matched by any other metals or

synthetic substitutes discovered to date. While they are called

‘rare earth metals’, some are relatively abundant in

the Earth’s crust, but extraction is costly and highly

polluting. David Abraham describes the mining of dysprosium and

Terbium used in a variety of high-tech devices in Jianxi, China.

He writes, “Only 0.2 percent of the mined clay contains the

valuable rare earth elements. This means that 99.8 percent of

earth removed in rare earth mining is discarded as waste called

‘tailings’ that are dumped back into the hills and

streams,” creating new pollutants like

ammonium.[Ibid., 175.] In

order to refine one ton of rare earth elements, “the

Chinese Society of Rare Earths estimates that the process

produces 75,000 liters of acidic water and one ton of radioactive

residue.”[Ibid., 176.]

Furthermore, mining and refining activities

consume vast amount of water and generate large quantities of CO2

emissions. In 2009, China produced 95% of the world’s

supply of these elements, and it has been estimated that the

single mine known as

Bayan Obo contains 70%

of the world’s reserves.[Chris Lo,

“The False Monopoly: China and the Rare Earths Trade,”

Mining Technology, 19 Aug 2015.]

Elements - Geological process

XIV

A satellite picture of the tiny Indonesian

island of Bangka tells

a story about human and environmental toll of the semiconductor

production. On this tiny island, mostly ‘informal’

miners are on makeshift pontoons, using bamboo poles to scrape

the seabed, and then diving underwater to suck tin from the

surface through giant, vacuum-like tubes. As a Guardian

investigation reports “tin mining is a lucrative but

destructive trade that has scarred the island’s landscape,

bulldozed its farms and forests, killed off its fish stocks and

coral reefs, and dented tourism to its pretty palm-lined beaches.

The damage is best seen from the air, as pockets of lush forest

huddle amid huge swaths of barren orange earth. Where not

dominated by mines, this is pockmarked with graves, many holding

the bodies of miners who have died over the centuries digging for

tin.”[Kate Hodal,

“Death Metal: Tin Mining in Indonesia,”

The Guardian, 23 Nov 2012.]

Two small islands, Bangka and Belitung,

produce 90% of Indonesia’s tin, and Indonesia is the world’s

second-largest exporter of the metal. Indonesia’s national tin

corporation, PT Timah, supplies companies such as Samsung

directly, as well as solder makers Chernan and Shenmao, which in

turn supply Sony, LG and

Foxconn.[Cam Simpson,

“The Deadly Tin Inside Your Smartphone,”

Bloomberg, 24 Aug 2012.]

XV

At Amazon distribution centers, vast collections of products are

arrayed in a computational order across millions of shelves. The

position of every item in this space is precisely determined by

complex mathematical functions that process information about

orders and create relationships between products. The aim is to

optimize the movements of the robots and humans that collaborate

in these warehouses. With the help from an electronic bracelet,

the human worker is directed though warehouses the size of

airplane hangars, filled with objects arranged in an opaque

algorithmic order.[Marcus Wohlsen, “A Rare Peek Inside Amazon’s Massive Wish-Fulfilling Machine,” Wired, 16 Jun 2014.]

Hidden among the thousands of other publicly available patents

owned by Amazon, U.S. patent number 9,280,157 represents an

extraordinary illustration of worker alienation, a stark moment

in the relationship between humans and machines.[Wurman, Peter R. et al.,

System and Method for Transporting Personnel Within an Active Workspace, US 9,280,157 B2 (Reno, NV, filed 4 Sep 2013, and issued 8 Mar 2016).]

It depicts a metal cage intended for the worker, equipped with different

cybernetic add-ons, that can be moved through a warehouse by the

same motorized system that shifts shelves filled with

merchandise. Here, the worker becomes a part of a machinic

ballet, held upright in a cage which dictates and constrains

their movement.

As we have seen time and time again in the research for our map,

dystopian futures are built upon the unevenly distributed

dystopian regimes of the past and present, scattered through an

array of production chains for modern technical devices. The

vanishingly few at the top of the fractal pyramid of value

extraction live in extraordinary wealth and comfort. But the

majority of the pyramids are made from the dark tunnels of mines,

radioactive waste lakes, discarded shipping containers, and

corporate factory dormitories.

XVI

At the end of 19th century, a particular Southeast Asian tree

called palaquium gutta became the center of a technological boom.

These trees, found mainly in Malaysia, produce a milky white

natural latex called gutta percha. After English scientist

Michael Faraday published a study in The Philosophical Magazine

in 1848 about the use of this material as an electrical

insulator, gutta percha rapidly became the darling of the

engineering world. It was seen as the solution to the problem of

insulating telegraphic cables in order that they could withstand

the conditions of the ocean floor. As the global submarine

business grew, so did demand for palaquium gutta tree trunks. The

historian John Tully describes how local Malay, Chinese and Dayak

workers were paid little for the dangerous works of felling the

trees and slowly collecting the

latex.[John Tully,

“A Victorian Ecological Disaster: Imperialism, the Telegraph, and Gutta-Percha,”

Journal of World History 20, no. 4 (23 Dec 2009): 559-79.]

The latex was processed

then sold through Singapore’s trade markets into the

British market, where it was transformed into, among other

things, lengths upon lengths of submarine cable sheaths.

A mature palaquium gutta could yield around 300 grams of latex.

But in 1857, the first transatlantic cable was around 3000 km

long and weighed 2000 tons — requiring around 250 tons of

gutta percha. To produce just one ton of this material required

around 900,000 tree trunks. The jungles of Malaysia and Singapore

were stripped, and by the early 1880s the palaquium gutta had

vanished. In a last-ditch effort to save their supply chain, the

British passed a ban in 1883 to halt harvesting the latex, but

the tree was already extinct.[Ibid., 574.]

The Victorian environmental disaster of gutta percha, from the

early origins of the global information society, shows how the

relationships between technology and its materiality,

environments, and different forms of exploitation are imbricated.

Just as Victorians precipitated ecological disaster for their

early cables, so do rare earth mining and global supply chains

further imperil the delicate ecological balance of our era.

From

the material used to build the technology enabling contemporary

networked society, to the energy needed for transmitting,

analyzing, and storing the data flowing through the massive

infrastructure, to the materiality of infrastructure: these deep

connections and costs are more significant, and have a far longer

history, than is usually represented in the corporate imaginaries

of AI.[See

Nicole Starosielski, The Undersea Network

(Durham: Duke University Press Books, 2015)

isbn.nu,

worldcat.]

XVII

Large-scale AI systems consume enormous amounts of energy. Yet

the material details of those costs remain vague in the social

imagination. It remains difficult to get precise details about

the amount of energy consumed by cloud computing services. A

Greenpeace report states: “One of the single biggest

obstacles to sector transparency is Amazon Web Services (AWS).

The world’s biggest cloud computer company remains almost

completely non-transparent about the energy footprint of its

massive operations. Among the global cloud providers, only AWS

still refuses to make public basic details on the energy

performance and environmental impact associated with its

operations.”[Gary Cook,

“Clicking Clean: Who Is Winning the Race to Build a Green Internet?”

(Washington, DC: Greenpeace, January 2017),

30.]

As human agents, we are visible in almost every interaction with

technological platforms. We are always being tracked, quantified,

analyzed and commodified. But in contrast to user visibility, the

precise details about the phases of birth, life and death of

networked devices are obscured. With emerging devices like the

Echo relying on a centralized AI infrastructure far from view,

even more of the detail falls into the shadows.

Amazon Infrastructure

While consumers become accustomed to a small hardware device in

their living rooms, or a phone app, or a semi-autonomous car, the

real work is being done within machine learning systems that are

generally remote from the user and utterly invisible to her. In

many cases, transparency wouldn’t help much—without

forms of real choice, and corporate accountability, mere

transparency won’t shift the weight of the current power

asymmetries.[Mike Ananny and

Kate Crawford,

“Seeing without knowing: Limitations of the transparency ideal and its application to algorithmic accountability,”

New Media & Society 20.3 (2018): 973-989.]

The outputs of machine learning systems are predominantly

unaccountable and ungoverned, while the inputs are enigmatic. To

the casual observer, it looks like it has never been easier to

build AI or machine learning-based systems than it is today.

Availability of open-source tools for doing so in combination

with rentable computation power through cloud superpowers such as

Amazon (AWS), Microsoft (Azure), or Google (Google Cloud) is

giving rise to a false idea of the ‘democratization’

of AI. While ‘off the shelf’ machine learning tools,

like TensorFlow, are becoming more accessible from the point of

view of setting up your own system, the underlying logics of

those systems, and the datasets for training them are accessible

to and controlled by very few entities. In the dynamic of dataset

collection through platforms like Facebook, users are feeding and

training the neural networks with behavioral data, voice, tagged

pictures and videos or medical data. In an era of extractivism,

the real value of that data is controlled and exploited by the

very few at the top of the pyramid.

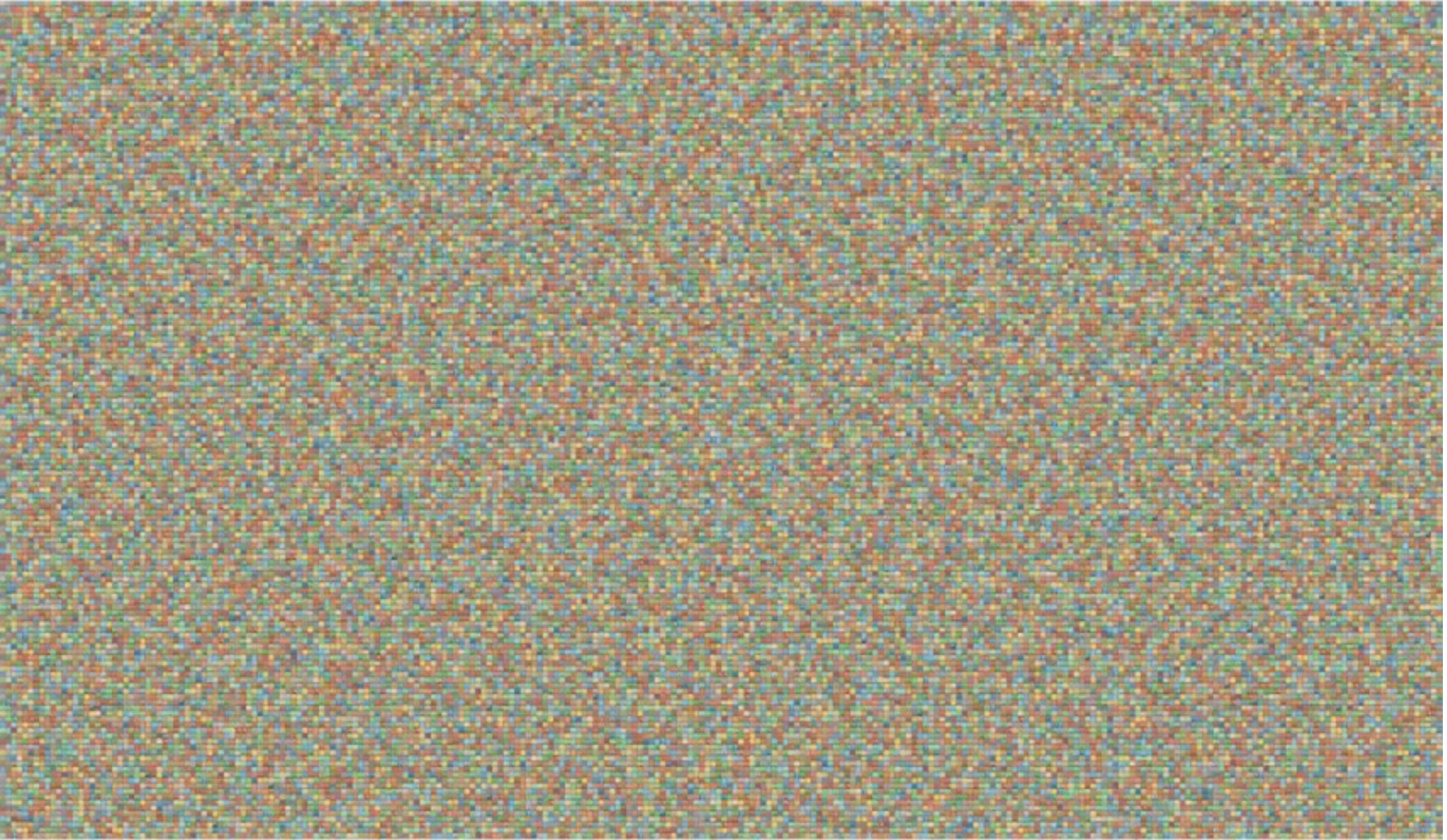

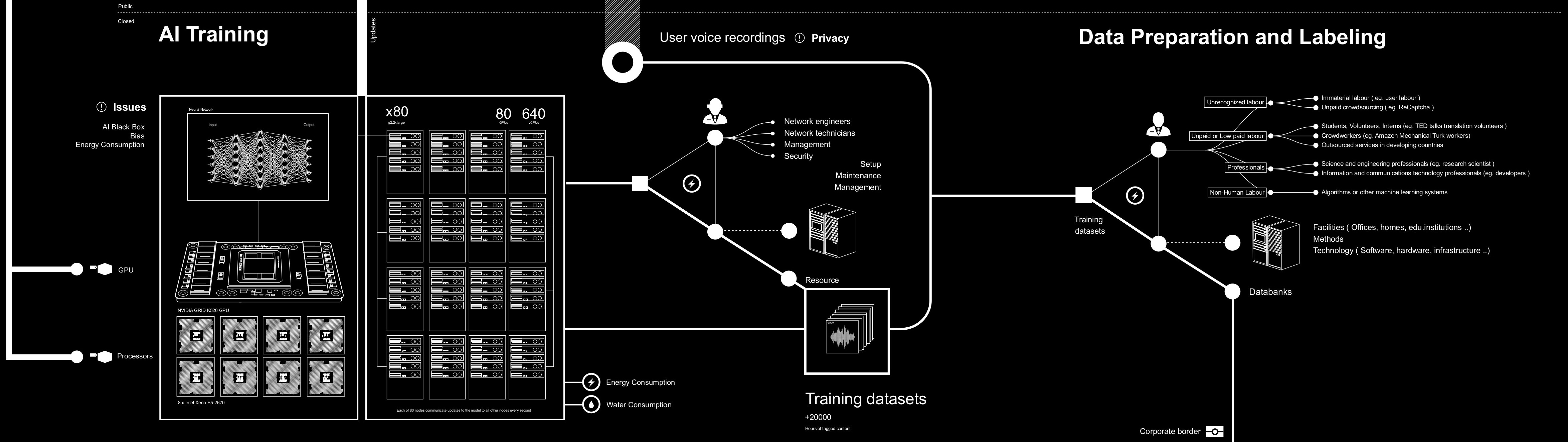

AI Training

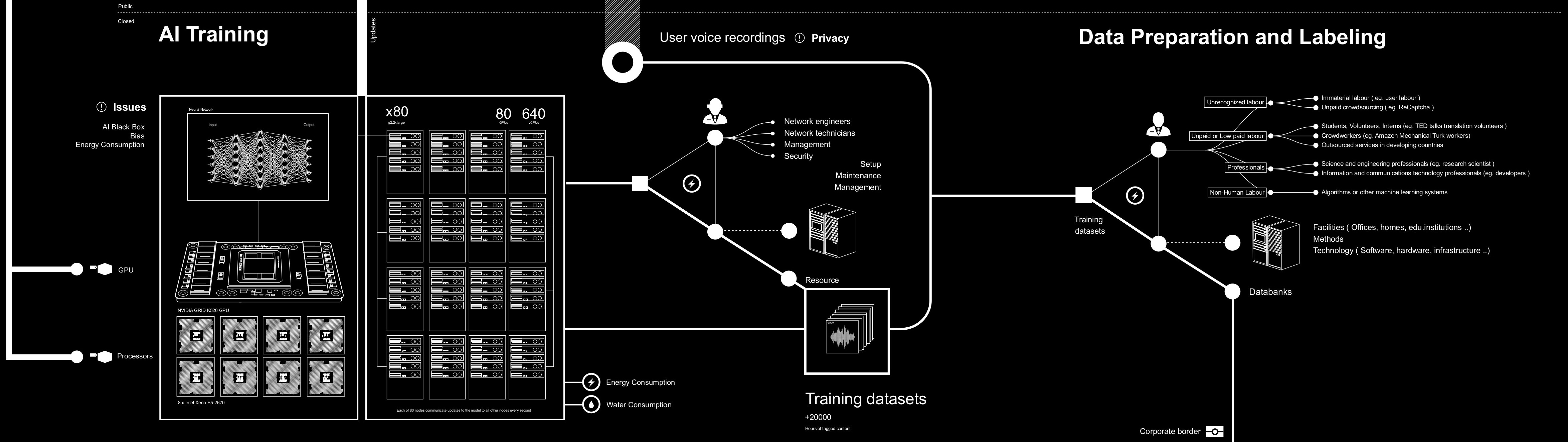

XVIII

When massive data sets are used to train AI systems, the

individual images and videos involved are commonly tagged and

labeled.[Olga Russakovsky et al.,

“ImageNet Large Scale Visual Recognition Challenge,”

International Journal of Computer Vision 115, no. 3 (1 Dec 2015): 216.]

There is much to be said about how this labelling

process abrogates and crystallizes meaning, and further, how this

process is driven by clickworkers being paid fractions of a cent

for this digital piecework.

In 1770, Hungarian inventor Wolfgang von Kempelen constructed a

chess-playing machine known as the Mechanical Turk. His goal, in

part, was to impress Empress Maria Theresa of Austria. This

device was capable of playing chess against a human opponent and

had spectacular success winning most of the games played during

its demonstrations around Europe and the Americas for almost nine

decades. But the Mechanical Turk was an illusion that allowed a

human chess master to hide inside the machine and operate it.

Some 160 years later, Amazon.com branded its micropayment based

crowdsourcing platform with the same name. According to Ayhan

Aytes, Amazon’s initial motivation to build Mechanical Turk

emerged after the failure of its artificial intelligence programs

in the task of finding duplicate product pages on its retail

website.[Ayhan Aytes,

“Return of the Crowds: Mechanical Turk and Neoliberal States of Exception,” in

Digital Labor: The Internet as Playground and Factory, ed. Trebor Scholz (London: Routledge, 2012), 80

(worldcat).] After a series of futile and expensive attempts, the

project engineers turned to humans to work behind computers

within a streamlined web-based system.[Jason Pontin, “Artificial Intelligence, With Help From the Humans,” The New York Times, 25 Mar 2007, sec. Business Day.] Amazon Mechanical Turk

digital workshop emulates artificial intelligence systems by

checking, assessing and correcting machine learning processes

with human brainpower. With Amazon Mechanical Turk, it may seem

to users that an application is using advanced artificial

intelligence to accomplish tasks. But it is closer to a form of

‘artificial artificial intelligence’, driven by a

remote, dispersed and poorly paid clickworker workforce that

helps a client achieve their business objectives. As observed by

Aytes, “in both cases [both the Mechanical Turk from 1770

and the contemporary version of Amazon’s service] the

performance of the workers who animate the artifice is obscured

by the spectacle of the machine.”[Aytes, “Return of the Crowds,”

81.]

This kind of invisible, hidden labor, outsourced or crowdsourced,

hidden behind interfaces and camouflaged within algorithmic

processes is now commonplace, particularly in the process of

tagging and labeling thousands of hours of digital archives for

the sake of feeding the neural networks. Sometimes this labor is

entirely unpaid, as in the case of the Google’s reCAPTCHA.

In a paradox that many of us have experienced, in order to prove

that you are not artificial agent, you are forced to train

Google’s image recognition AI system for free, by selecting

multiple boxes that contain street numbers, or cars, or houses.

As we see repeated throughout the system, contemporary forms of

artificial intelligence are not so artificial after all. We can

speak of the hard physical labor of mine workers, and the

repetitive factory labor on the assembly line, of the cybernetic

labor in distribution centers and the cognitive sweatshops full

of outsourced programmers around the world, of the low paid

crowdsourced labor of Mechanical Turk workers, or the unpaid

immaterial work of users. At every level contemporary technology

is deeply rooted in and running on the exploitation of human

bodies.

XIX

In his one-paragraph short story “On Exactitude in

Science”, Jorge Luis Borges presents us with an imagined

empire in which cartographic science became so developed and

precise, that it needed a map on the same scale as the empire

itself.[Jorge Luis Borges,

“On Exactitude in Science,” in

Collected Fictions, trans. Andrew Hurley

(New York: Penguin, 1999),

325.]

“...In that Empire, the Art of Cartography attained such

Perfection that the map of a single Province occupied the

entirety of a City, and the map of the Empire, the entirety of a

Province. In time, those Unconscionable Maps no longer satisfied,

and the Cartographers Guilds struck a Map of the Empire whose

size was that of the Empire, and which coincided point for point

with it. The following Generations, who were not so fond of the

Study of Cartography as their Forebears had been, saw that that

vast map was Useless, and not without some Pitilessness was it,

that they delivered it up to the Inclemencies of Sun and Winters.

In the Deserts of the West, still today, there are Tattered Ruins

of that Map, inhabited by Animals and Beggars; in all the Land

there is no other Relic of the Disciplines of Geography.”

Current machine learning approaches are characterized by an

aspiration to map the world, a full quantification of visual,

auditory, and recognition regimes of reality. From cosmological

model for the universe to the world of human emotions as

interpreted through the tiniest muscle movements in the human

face, everything becomes an object of quantification.

Jean-François Lyotard introduced the phrase

“affinity to infinity” to describe how contemporary

art, techno-science and capitalism share the same aspiration to

push boundaries towards a potentially infinite

horizon.[Jean Francois Lyotard,

“Presenting the Unpresentable: The Sublime,”

Artforum, Apr 1982.] The

second half of the 19th century, with its focus on the

construction of infrastructure and the uneven transition to

industrialized society, generated enormous wealth for the small

number of industrial magnates that monopolized exploitation of

natural resources and production processes.

The new infinite horizon is data extraction, machine learning,

and reorganizing information through artificial intelligence

systems of combined human and machinic processing. The

territories are dominated by a few global mega-companies, which

are creating new infrastructures and mechanisms for the

accumulation of capital and exploitation of human and planetary

resources.

Such unrestrained thirst for new resources and fields of

cognitive exploitation has driven a search for ever deeper layers

of data that can be used to quantify the human psyche, conscious

and unconscious, private and public, idiosyncratic and general.

In this way, we have seen the emergence of multiple cognitive

economies from the attention

economy,[Yves Citton,

The Ecology of Attention

(Cambridge, UK: Polity, 2017).] the surveillance

economy, the reputation economy,[Shoshana Zuboff,

“Big Other: Surveillance Capitalism and the Prospects of an Information Civilization,”

Journal of Information Technology 30, no. 1 (1 Mar 2015):

75-89.] and the emotion economy, as

well as the quantification and commodification of trust and

evidence through cryptocurrencies.

Increasingly, the process of quantification is reaching into the

human affective, cognitive, and physical worlds. Training sets

exist for emotion detection, for family resemblance, for tracking

an individual as they age, and for human actions like sitting

down, waving, raising a glass, or crying. Every form of biodata

— including forensic, biometric, sociometric, and

psychometric — are being captured and logged into databases

for AI training. That quantification often runs on very limited

foundations: datasets like AVA which primarily shows women in the

‘playing with children’ action category, and men in

the ‘kicking a person’ category. The training sets

for AI systems claim to be reaching into the fine-grained nature

of everyday life, but they repeat the most stereotypical and

restricted social patterns, re-inscribing a normative vision of

the human past and projecting it into the human future.

XX

“The ‘enclosure’ of biodiversity and knowledge

is the final step in a series of enclosures that began with the

rise of colonialism. Land and forests were the first resources to

be ‘enclosed’ and converted from commons to

commodities. Later on, water resources were

‘enclosed’ through dams, groundwater mining and

privatization schemes. Now it is the turn of biodiversity and

knowledge to be ‘enclosed’ through intellectual

property rights (IPRs),” Vandana Shiva explains.[Vandana Shiva,

The Enclosure and Recovery of The Commons: Biodiversity, Indigenous Knowledge, and Intellectual Property Rights

(Research Foundation for Science, Technology, and Ecology, 1997).] In

Shiva’s words, “the destruction of commons was

essential for the industrial revolution, to provide a supply of

natural resources for raw material to industry. A life-support

system can be shared, it cannot be owned as private property or

exploited for private profit. The commons, therefore, had to be

privatized, and people’s sustenance base in these commons

had to be appropriated, to feed the engine of industrial progress

and capital accumulation.”[Vandana Shiva,

Protect or Plunder: Understanding Intellectual Property Rights

(New York: Zed Books, 2001).]

While Shiva is referring to enclosure of nature by intellectual

property rights, the same process is now occurring with machine

learning — an intensification of quantified nature. The new

gold rush in the context of artificial intelligence is to enclose

different fields of human knowing, feeling, and action, in order

to capture and privatize those fields. When in November 2015

DeepMind Technologies Ltd. got access to the health records of

1.6 million identifiable patients of Royal Free hospital, we

witnessed a particular form of privatization: the extraction of

knowledge value.[Alex Hern,

“Royal Free Breached UK Data Law in 1.6m Patient Deal with Google’s DeepMind,”

The Guardian, 3 Jul 2017, sec. Technology.] A dataset may

still be publicly owned, but the meta-value of the data —

the model created by it — is privately owned. While there

are many good reasons to seek to improve public health, there is

a real risk if it comes at the cost of a stealth privatization of

public medical

services. That is a future where expert local human labor in the

public system is augmented and sometimes replaced with

centralized, privately-owned corporate AI systems, that are using

public data to generate enormous wealth for the very few.

XXI

At this moment in the 21st century, we see a new form of

extractivism that is well underway: one that reaches into the

furthest corners of the biosphere and the deepest layers of human

cognitive and affective being. Many of the assumptions about

human life made by machine learning systems are narrow, normative

and laden with error. Yet they are inscribing and building those

assumptions into a new world, and will increasingly play a role

in how opportunities, wealth, and knowledge are distributed.

The stack that is required to interact with an Amazon Echo goes

well beyond the multi-layered ‘technical stack’ of

data modeling, hardware, servers and networks. The full stack

reaches much further into capital, labor and nature, and demands

an enormous amount of each. The true costs of these systems

— social, environmental, economic, and political —

remain hidden and may stay that way for some time.

We offer up this map and essay as a way to begin seeing across a

wider range of system extractions. The scale required to build

artificial intelligence systems is too complex, too obscured by

intellectual property law, and too mired in logistical complexity

to fully comprehend in the moment. Yet you draw on it every time

you issue a simple voice command to a small cylinder in your

living room: ‘Alexa, what time is it?”

And so the cycle continues.

back to collapsologie |

rat haus |

Index |

Search |

tree