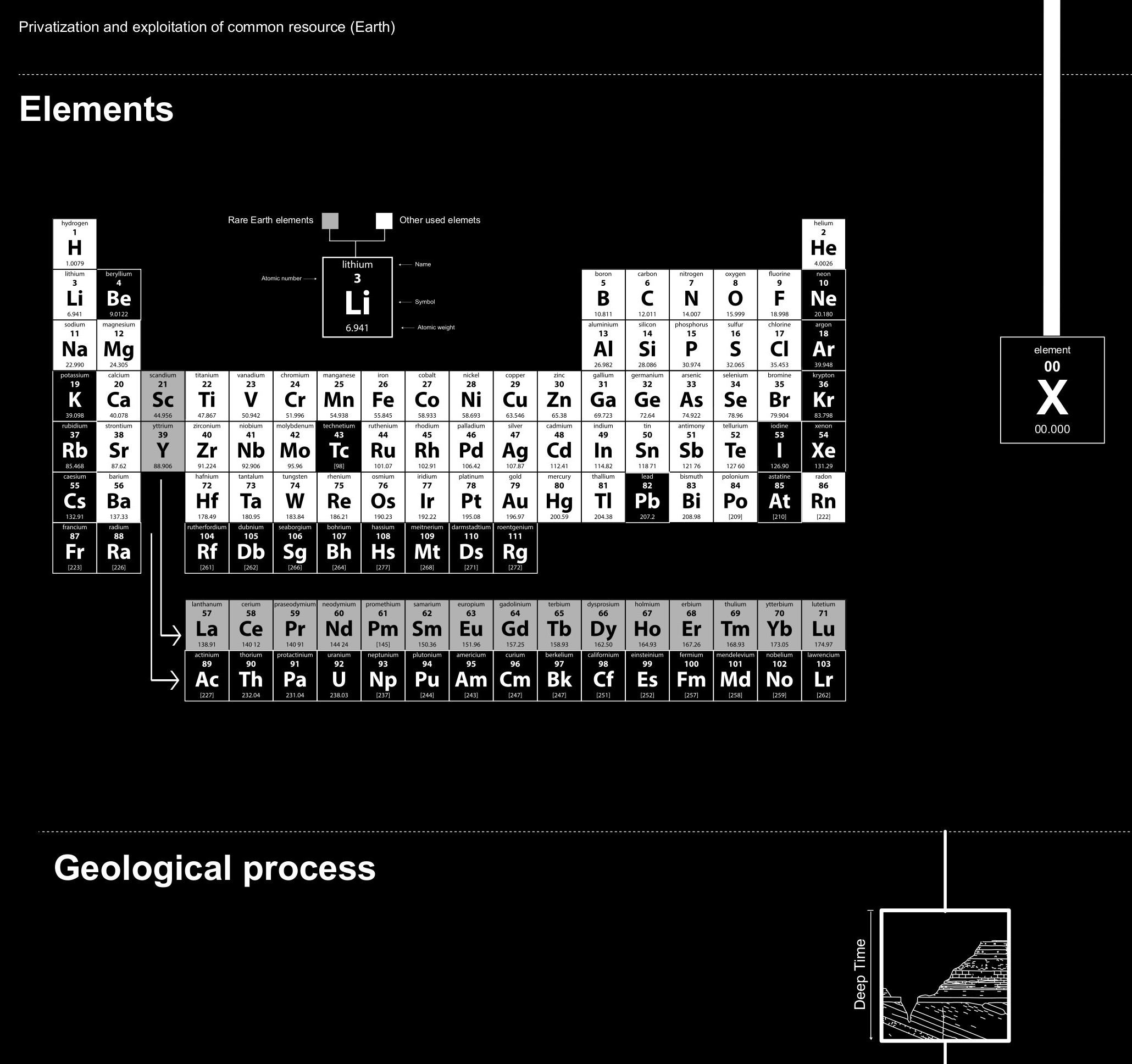

The unique electronic, optical and magnetic characteristics of rare earth elements cannot be matched by any other metals or synthetic substitutes discovered to date. While they are called ‘rare earth metals’, some are relatively abundant in the Earth’s crust, but extraction is costly and highly polluting. David Abraham describes the mining of dysprosium and Terbium used in a variety of high-tech devices in Jianxi, China. He writes, “Only 0.2 percent of the mined clay contains the valuable rare earth elements. This means that 99.8 percent of earth removed in rare earth mining is discarded as waste called ‘tailings’ that are dumped back into the hills and streams,” creating new pollutants like ammonium.[Ibid., 175.] In order to refine one ton of rare earth elements, “the Chinese Society of Rare Earths estimates that the process produces 75,000 liters of acidic water and one ton of radioactive residue.”[Ibid., 176.] Furthermore, mining and refining activities consume vast amount of water and generate large quantities of CO2 emissions. In 2009, China produced 95% of the world’s supply of these elements, and it has been estimated that the single mine known as Bayan Obo contains 70% of the world’s reserves.[Chris Lo, “The False Monopoly: China and the Rare Earths Trade,” Mining Technology, 19 Aug 2015.]

|